Inconel Alloy 625 Vs Inconel Alloy 718

Alloy 625 and Alloy 718, commonly referred to as Inconel 625 and Inconel 718, are both nickel alloys, both superalloys and they’re both a part of the Inconel family of alloys. So, what’s the difference between Inconel 625 vs 718?

What’s the difference between Inconel 625 vs 718?

We’ll break down the differences between Inconel 625 and Inconel 718 below, from chemical composition to recommended application. But first, a word on terminology.

Terminology

You might notice that we switch between Inconel 625 and alloy 625 throughout this article. Instead of leaving you to Google ‘Inconel 625 vs alloy 625’, we thought we’d explain what these names mean.

When we use the terms Inconel 625 and alloy 625, we are referring to the same alloy. Inconel is a registered trademark of the Special Metals Corporation. Thus, most alloy suppliers refer to it as alloy 625 instead of Inconel 625, for legal purposes.

Composition

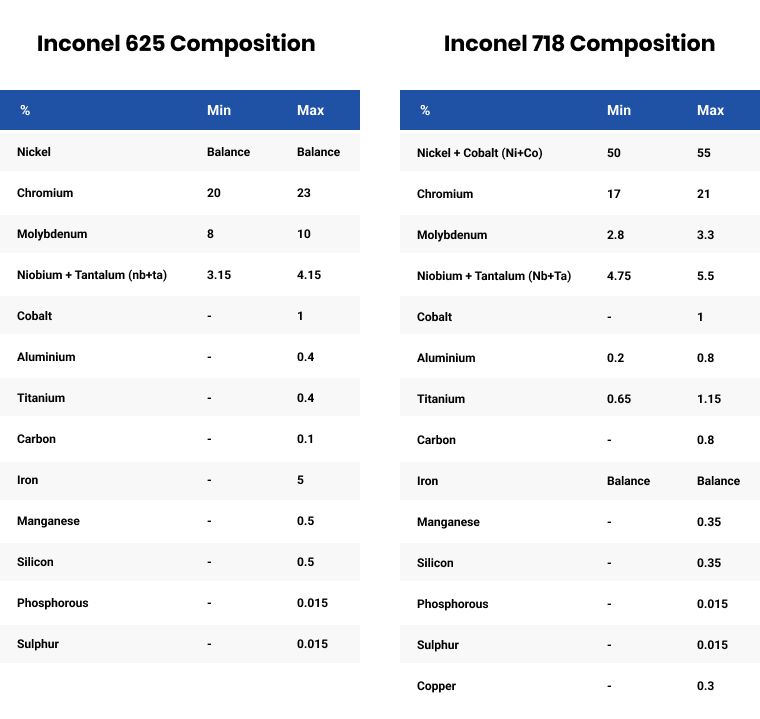

The first major difference between Inconel Alloy 625 vs 718 is their chemical composition. Both are nickel alloys, but each contains different amounts of a variety of chemicals which distinguish them.

Alloy 625 is primarily nickel-based, whilst Alloy 718 is nickel + cobalt (Ni+Co) based. The use of nickel + cobalt in Alloy 718 means that it has greater hardness and strength. Alloy 625, on the other hand, has higher levels of chromium and molybdenum, so it is more corrosion-resistant. See the full comparison of the chemical composition of Inconel 625 vs 718 below.

Properties

Inconel 625 and Inconel 718 share a number of common properties. Like most nickel alloys, both are high in strength, easily weldable and corrosion-resistant.

However, the different chemical compositions of both alloys mean that they display differing levels of these properties. Whilst both alloys are heat resistant, Alloy 718 has a higher melting range of 1321-1393°C. Similarly, whilst both demonstrate good corrosion resistance, the higher levels of chromium and molybdenum make Alloy 625 more corrosion resistant.

Application

Inconel 625 and Inconel 718 are suitable for a range of industries and applications. However, their respective composition and properties make each alloy excel in certain fields.

Inconel 625 Applications

Inconel 625 is most commonly used in the oil and gas industry due to its excellent corrosion resistance. This makes it the alloy of choice for subsea equipment. It is also used in corrosive environments in the aerospace industry, such as exhaust systems, furnace muffles and engine thrust-reversers.

Inconel 718 Applications

Inconel 718 is a pillar of the aerospace industry. Its exceptional heat resistance makes it ideal for application in high-temperature environments, including engine components. It is also used in high-performance car engines in the motorsport industry.

Product Forms

Both alloy 625 and 718 are easily formable and weldable, so they are readily available in a range of product forms.

Inconel 625 Product Forms

- Pipe

- Coil

- Welding Wire

- Sheet and Plate

- Round Bar

- Pipe Fittings

- Flanges

Inconel 718 Product Forms

- Round Bar

- Sheet and Plate

- Welding Wire

We hope this article has clarified the difference between Inconel 625 vs 718. NeoNickel are suppliers of speciality alloys throughout Europe. For more information on Alloy 625, Alloy 718 or any other alloy, please contact us or fill out our online form.