Radiant Tube Furnaces in Industrial Heating

Radiant Tube Heaters

Radiant tubes are a method of heating a furnace without contaminating the furnace atmosphere with the products of combustion.

The radiant tubes aim to transfer heat as uniformly as possible within the interior of the tube and transfer the heat within the furnace. The transfer of heat to the inner surface of the tube is dependent on the tube’s effective surface area.

A tube with a nominal inside diameter of 100 mm may have a much greater effective internal surface area due to surface roughness, which resembles small bumps and troughs. The internal surface area of the tube can also be increased using internal fins.

Cast or Fabricated (wrought)

Fabricated tubes offer several advantages compared to cast tubes.

Fabricated radiant tubes offer significant weight savings versus cast tubes, for example, if a 3 mm wall, 150 mm Ø fabricated tube manufactured from 602 CA® weighs approximately 75 Kgs an equivalent 6 mm cast tube weighs around 170 Kgs.

Thin-walled, lightweight tubes resist sagging and cracking and have a high resistance to thermal fatigue and better heat transfer. They are also more ductile and therefore less likely to fracture at the joints.

Also, fabricated tube components, return bends, flanges, bungs, and straights can be repaired or replaced on-site, saving time and costs. Also, wrought fabricated materials are free of external and internal defects that might be present in cast tubes.

Regarding up-front costs, cast tubes might be slightly cheaper but the higher weight coupled with longer lead times, increased energy costs and furnace downtime for replacement indicates fabricated tubes are the best option in most applications.

Radiant Tube Failure

Once installed it is difficult to inspect radiant tube heaters. Several reasons typically lead to premature failure, which can cause expensive production delays.

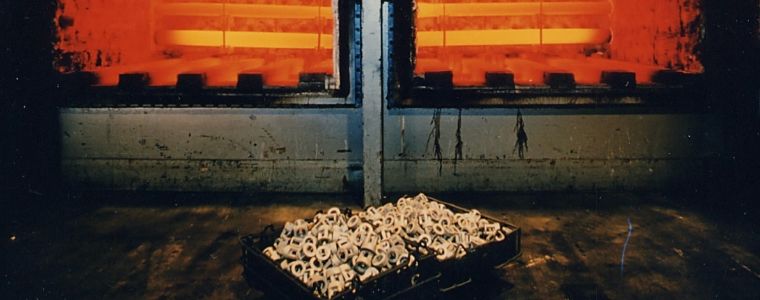

Radiant Tube Furnace

Radiant tubes can last anywhere between 1 and 5 years depending on the furnace and how it is designed and used, therefore it is useful to understand the common causes of premature failure and how to avoid them.

Burner alignment and calibration

Burner alignment is critical to the longevity of a radiant tube furnace to avoid ‘flame impingement’, caused by the flame being in contact with the tube causing a hot spot.

For optimal operation the flame and tube should not contact, as the flame attempts to burn through the tube it will eventually cause failure.The ratio of gas and air, referred to as calibration, is also necessary to avoid an excessive carbon build-up which causes hot spots and can lead to a rapid deterioration of the metal.

Improper joint fusion (welding)

Joints in fabricated or cast tubes must be properly prepared or premature failure of the tube joints will occur.

Meticulous care must be taken of the areas to be welded to maximise the operating life of the tube.

Constant Thermal Cycling

A radiant tube furnace is designed to run 24/7. Some manufacturers will cycle their furnaces, turning them down during weekends or holiday shutdowns, this should be done with the understanding that reducing the operating costs and saving energy could adversely affect the operating life of the tubes.

Alloys

Radiant tube heaters operate in the range of 600 – 1250oC depending on the materials used. They must be resistant to high-temperature corrosion and creep resistant.

Typically, fabricated radiant tubes using high-nickel, low-carbon alloys with a controlled tight grain structure will offer a longer operating life, and reduced maintenance and energy costs.

Alloy 253 MA® offers an outstanding combination of creep strength and high resistance to oxidation and sulphidation at extremely high temperatures. The high heat-resistant properties of 253 MA® are obtained by the tight control of micro-alloy additions.

Whilst the benefit of creep rupture strength is down to the combination of nitrogen, carbon and cerium, its superior oxidation resistance is a result of the combination of cerium and silicon.

Alloy 310S displays excellent resistance to oxidation under mildly cyclic conditions. As a result of its high chromium and nickel content, Alloy 310S has good resistance to sulphidation and other forms of hot corrosion.

Alloy 601 develops a tightly adherent oxide scale which resists spalling even under severe thermal cycling. This alloy has good high-temperature strength and retains its ductility after long service exposure, with good corrosion resistance under oxidizing conditions.

Alloy 602CA® is extensively used in thermal processing equipment with a high creep rupture strength, providing up to 150% of the strength of other Nickel Alloys. Due to its high Nickel content, 602 CA® has an outstanding resistance to carburisation, ensuring prolonged ductility in the face of carbon monoxide (CO) and methane (CH4).

Alloy RA330® is the workhorse of heat-resistant alloys with good strength and oxidising resistance. In addition, the alloy is excellent in carburising and nitriding environments. RA330® finds wide applications in high-temperature environments where good resistance to the combined effect of carburisation and thermal cycling conditions is the prime requisite.

Alloy 602 CA® Radiant tubes fabricated for Syracuse Heat Treatment Corporation.

253 MA® is the registered trademark of Outokumpu Stainless

602CA® is the registered trademark of VDM Metals International GMBH

RA330® is the registered trademark of Rolled Alloys Inc

FAQs

Are radiant tube heaters efficient?

Radiant tube heaters offer an efficient way to heat spaces, both in terms of energy consumption and the effectiveness of the heat they produce. Their ability to provide direct, uniform heating with reduced energy use makes them a compelling choice for those looking to optimise their heating solutions.

Is a radiant heater cheap to run?

Radiant heaters can be relatively cheap to run. Their efficiency and targeted heating capabilities make them a cost-effective option for many users, though the exact running costs will depend on individual circumstances and the specific type of radiant heater used.

Do radiant heaters really work?

Radiant heaters are effective, particularly in providing direct, localised heat with minimal energy waste. Their functionality in both indoor and outdoor settings, along with the immediate warmth they provide, makes them a practical heating solution for various scenarios.

What does a radiant tube heater do?

A radiant tube heater offers a highly efficient solution for warming large areas. Its capacity to conserve energy enhances its appeal, making it a favoured option in diverse settings, including commercial, industrial and outdoor environments.