Alloy 22 in Claus Technology

Case Study on Alloy 22 in a Coking Plant Application Sulphur Recovery Application Utilising Split Claus Technology

Alloy 22 fittings were supplied by NeoNickel for use in a coke refining/briquetting plant helping to resist aqueous corrosion and high temperature corrosion in its coke oven gas (COG) handling process environment. This improved efficiency in the plant, adding value, contributing to revenue and protecting the environment from pollutants.

Alloy 22 pipework was used in the scrubber/refining process on the coke plant. Material supplied included alloy 22 welded pipes, concentric elbows & reducers, equal tees, reducing tees, end caps, loose & blind flanges, spectacle flanges, lap joint flanges and DIN collars. Alloy 22 was proven to have superior corrosion resistance in coke refining applications.

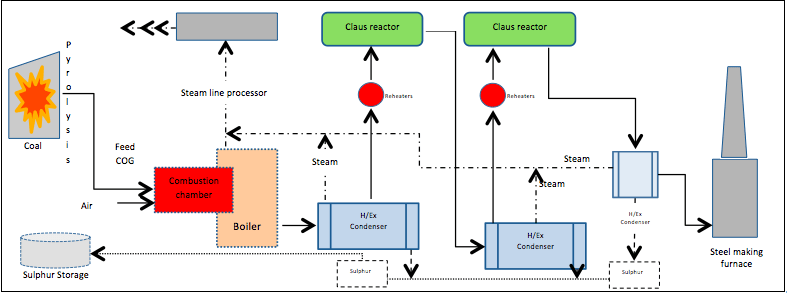

The alloy 22 pipes, fittings and flanges were used in the modification/retrofit application in the coking plant in Poland. The process used the split-Claus technology for sulphur recovery during the COG treatment process. Coke oven gas was produced via pyrolysis of bituminous coal, alongside coke by-products – tar, ammonia, naphthalene, sulphur, etc. The input feed gas contained tar, caustic, reducing and oxidizing sulphur, reducing and oxidizing carbon, ammonia, liquor, etc. Split Claus technology was an integrated technology applied for the reduction of emissions of pollutants from the coke oven gas to deliver clean fuel gas for use in the steel making process. Output process gas was clean COG, condensed tar, waste water, tail gas, sulphur, etc. Sulphur was recovered (as a valuable commercial by-product) by condensation, as the process gas was cooled in a high pressure waste boiler and steam generated.

The COG contained a variety of species and chemicals which were potentially dangerous and corrosive under certain conditions. Alloy 22 was chosen based on these diverse stream compositions and operating conditions. Moreover, alloy 22 was also used because of its better crevice corrosion resistance, excellent pitting corrosion resistance and close to zero corrosion rate in process fluids having both oxidizing and reducing characteristics, emanating from units. Sometimes operating temperatures could vary from 20°C through to 300°C or even above 950°C in the waste heat boilers and combustion chambers.

| Corrosion rate for Refinery Industry | ||

| Vaporiser 95°C for 2 months | ||

| Alloys | Corrosion Rate (mm/y) | Note |

| 316L Stainless Steel | 3.53 | Severe Crevice Attack |

| Alloy 20 | 5.76 | Partially dissolved |

| 254SMO | 2.11 | Pitting, Crevice attack |

| 625 | 0.74 | Pitting, Crevice attack |

| 22 | 0.0086 | Slight crevice attack |