Swimming Pools – ZERON® 100

Recently there has been a dramatic rise in the use of brines in swimming pools. Possessing a disinfectant quality and electrolytically generating chlorine to provide disinfection the chloride content is much higher than older style pools. Therefore the water is more corrosive towards a lot of materials.

Stainless steels are often used for fittings in pools because they are easy to clean and corrosion resistant, which is extremely desirable. However, with added levels of chloride content common grades of stainless including 316L are exposed to corrosion.

300 series austenitic stainless steels have also been used for other uses including wire, bolts and bars to support swimming pool roofs. However these alloys are no longer desirable following several major failures.

Below describes the laboratory testing of ZERON® 100 superduplex stainless steel in both seawater and the swimming pool roof environment. We’ve included some service experiences.

The Alloy

50% ferrite and 50% austentine ZERON® 100 superduplex stainless steel has the benefits of austenitic microstructure and those of the ferritic microstructure.

50% ferrite and 50% austentine ZERON® 100 superduplex stainless steel has the benefits of austenitic microstructure and those of the ferritic microstructure.

Compared to other stainless steels ZERON® 100 has high levels of chromium, molybdenum and nitrogen which gives excellent resistance to localised attack in presence of chlorides. Typically, this is assessed by the pitting resistance equivalent number, PREN, where PREN = %CR + 3.3 X % MO + 16 X %N. The minimum PREN of 40 for ZERON® 100 ensures a high resistance to localised attack in chloride solutions.

Manufactured by a variety of processes ZERON® 100 is available as castings and as wrought pipes, fittings, plate, bar, fasteners and forgings. It’s also available as a lightly cold worked bar in the FG condition where higher strength is required. This has similar mechanical properties to B7 steel, with the minimum mechanical properties being 725 MPa 0.2% proof stress and 860 MPa tensile strength.

ZERON® 100 can be welded using all the common arc welding processes and can be welded with ZERON® 100M consumables, where post weld heat treatment is to be carried out. It is most commonly welded with ZERON® 100X overalloyed consumables, for use in the as-welded condition. ZERON® requires lots of care during welding and it’s to use qualified welders who are qualified and use approved procedures.

Corrosion Resistance

Seawater

Typically swimming pools are chlorinated and the resistance to crevice corrosion of stainless steel in this environment has undergone numerous assessments. Results show the maximum depth of attack for several stainless steels in chlorinated seawater at 16°C, whilst alloy 904L generally suffers crevice corrosion to a lesser depth than 22% Cr duplex.

Typically swimming pools are chlorinated and the resistance to crevice corrosion of stainless steel in this environment has undergone numerous assessments. Results show the maximum depth of attack for several stainless steels in chlorinated seawater at 16°C, whilst alloy 904L generally suffers crevice corrosion to a lesser depth than 22% Cr duplex.

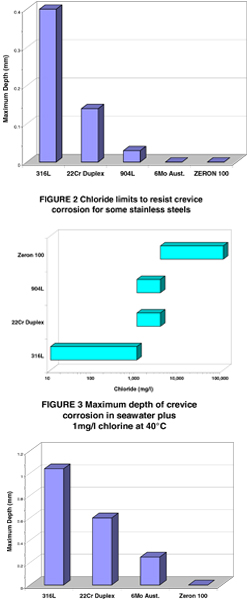

The Corrosion Engineering Guide can be used to calculate the maximum chloride content before crevice corrosion which can become a serious problem. Even at normal temperature 316L has a limited tolerance to chlorides. 904L and 22% Cr duplex can both be used in brackish waters, whilst only superduplex can be used where higher chloride content occurs. Usually seawater has around 18,000 to 25,000 mg/l chloride and the limits of 6% Mo austenitic stainless steel are comparable to those of ZERON® 100.

The susceptibility of stainless steels to crevice corrosion increases with rises in temperature. Results indicate the maximum depth of crevice corrosion for a number of stainless steels in chlorinated seawater is 40°C, whilst ZERON® 100 was resistant to attack.

#### Stress Corrosion CrackingStress Corrosion Cracking is usually seen at elevated temperatures when stainless steels are exposed to chlorides. However, a number of swimming pool roofs erected using 300 series stainless steel bolts and wire failed after a period of time which led to a number of investigations. The presence of chlorine in the water resulted in strong solutions condensing on the metal supports in the swimming pool roof and a low pH could develop. Results indicate that 316L stainless steel would be subject to stress corrosion cracking in measured condensed waters.

Studies show that 316L suffered corrosion cracking after 7 days of exposure to a simulated condensed water. The same test was done for ZERON® 100, during which no stress corrosion cracking was present.

Service Experience

With a low corrosion rate ZERON® 100 has been used for a number of fittings in seawater and high chloride brine swimming pools. ZERON® 100 bolts have also been used to fasten and secure a wide range of pool furniture in place.

With a low corrosion rate ZERON® 100 has been used for a number of fittings in seawater and high chloride brine swimming pools. ZERON® 100 bolts have also been used to fasten and secure a wide range of pool furniture in place.

Conclusions

Resisting corrosion in chlorinated swimming pools up to 40°C ZERON® 100 offers high strength and corrosion resistance superior to that of 316L austenitic stainless steel. Chloride stress corrosion cracking also occurs under the high chloride/low pH solutions that can condense and damage swimming pool roofs.

For more information on using ZERON® 100 for in swimming pools and other applications feel free to contact us today! ZERON® 100 is available in various formats and a number of finishes can be applied to achieve the products you desire.