What is an Alloy Metal? The Beginner’s Guide

Metal is a native element that’s become part of everyday life on planet earth. How would we live without it?

It builds our bridges, creates the structure of our offices, makes our cars, and is even part of the ring on our finger! We’ve mined various metals over time, such as gold, silver, copper, iron and nickel; and continue to do so today.

However, metal doesn’t have to exist in its natural form; and much like breeding dogs or plants, metals can be transformed into something completely different.

This transformation often occurs to make it more suitable for purpose, and is used in the manufacturing of everything from a house key to a trumpet.

Adaptability means businesses often want to buy alloy metals and use them for high-quality products or components. But before you decide what alloy metal you want to buy, you should read this guide.

To help you figure that out, we’re going to address the following points:

1.1 What is the Definition of an Alloy?

1.3 Are Alloys Pure or Impure?

1.4 What Are Some Common Alloys?

3. What Are the Different Types of Alloy?

3.3 Substitutional & Interstitial Combinations

4. What is the Purpose of an Alloy?

4.1 6 Reasons Alloys Are Useful

4.5 Disadvantages of Pure Metals

4.6 The Advantages of Alloys Over Pure Metals

4.7 What Industries Use Alloys?

1. What is an Alloy?

What is the Definition of An Alloy?

As a noun, the following definition applies:

‘A metal made by combining two or more metallic elements, especially to give greater strength or resistance to corrosion’.

As a verb, the following definition applies:

‘mix (metals) to make an alloy’.

An alloy in noun form is the elements in the mixture, with the metal is the primary constituent.

In its verb form, alloying refers to mixing the constituents to create the alloy.

Alloy Terminology

Here are some terms you should get familiar with:

- Primary constituent – the natural metal, which is usually called the base, solvent or matrix.

- Secondary constituent – the added metal or gas, which is called the solute..

- Binary Alloy – an alloy with two constituents.

- Ternary Alloy – an alloy with three constituents.

- Quaternary Alloy – an alloy with four constituents.

- Quinary Alloy – an alloy with five constituents.

- Systems – Percentages in each of these mixtures can vary, so each alloy has its respective name to categorise these numbers. e.g. a ternary system.

Are Alloys Pure or Impure?

Although an alloy is technically an impure metal, there are impurities within alloy metals that can weaken it or make it less practical in some way.

Examples:

- Steel – hydrogen gas is harmful to steel because it causes flakes and hairline cracks.

- Aluminium – lithium, sodium and calcium can hurt the structural casting and moulding of the alloy.

Some alloys even take on the name of their pure counterpart, such as gold. The Karat system classifies gold, where 24 karat gold is considered pure, and all other classifications below that contain metals such as copper and zinc. The mixture makes gold an alloy, but it retains its original name.

Some items take on the terminology alloy as well, such as ‘car alloy wheels’.

What Are Some Common Alloys?

There are hundreds of alloys, but here are some of the most common:

- Amalgam – a combination of mercury, silver, tin copper and zinc which makes dental fillings.

- Sterling silver – a mixture of silver and copper which makes cutlery, medical equipment, jewellery and musical instruments.

- Magnox – a combination of aluminium and copper which makes nuclear reactors.

2. What is Alloying?

We’ve established that alloying is the process of combining several metallic elements to create a new composition, but what’s the theory behind it?

Why is Alloying Important?

Individual pure metals may possess certain properties like ductility and good electrical conductivity.

However, they may be lacking in other areas, which would make it less commercially viable. Alloying combines these beneficial properties to create something fit for purpose.

For example, by adding just 1% of carbon to pure iron, steel is made. Steel is lighter, more workable, and stronger, making it ideal for any structural building work.

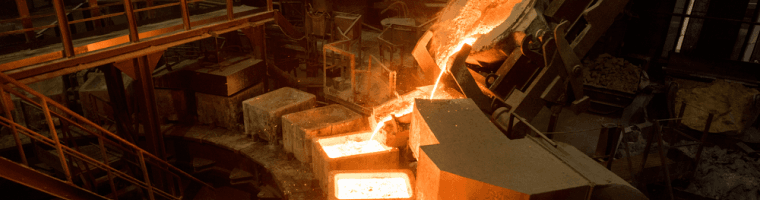

Common Method

The most common and oldest method of making an alloy is by heating the base metal beyond its melting point. You then add the solutes to the base mix which dissolves them into the base metal.

When you add another element to a metal, the size of the items create an internal stressor in the lattice of the metallic crystals, which often strengthens the properties of the metal.

For example, adding zinc to copper produces a more ductile alloy. Different mixtures yield different results, such as making the alloy more malleable, more reactive or stronger.

Even a small addition of other elements can change the composition of the metal. It’s a bit like cooking, where adding a tablespoon of cornflour where the flour particles would change the structure of the dish.

Eutectic Mixtures

Alloys do not always have a single melting point due to the different constituents that make them and often vary between solid and slush.

For example, Galinstan is a low-melt alloy which is liquid above -19 degrees, but 50 degrees below the melting point of its base metal gallium and 100 degrees below solutes indium and tin.

A eutectic mixture will ensure all of the elements liquefy at the same time. So while all the elements are different, Galinstan will melt at one temperature.

Metallurgy Process

The alloying process for each metal will vary due to its different properties. For example, titanium has a strong base which is capable of dissolving most metals and elements.

However, it burns in the process of nitrogen, which means it needs vacuum-induction melting and special copper crucibles to melt it.

Here are some examples:

- Nitriding – a heat-treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface.

- Carbonitriding – a surface modification technique that increases the surface hardness of the metal.

- Case hardening – hardening the surface of a metal while allowing the underlayer to remain soft.

While processes are advanced now, metals were being mixed as early as 4000 B.C. The Bronze Age gets its name from humans combining copper and tin to create bronze for tools and ornaments.

3. What Are the Different Types of Alloy?

There are three types of alloy: substitutional alloys, interstitial alloys and substitutional/interstitial alloys.

When molten metals mix, the structure of atoms in the mixture change as well, with the size of the atoms in the mix plays a huge part in which type of alloy is created.

Substitutional Alloys

When atoms are around the same size, an atom exchange will usually occur. An atom exchange is where some of the elements from the metallic crystals substitute with the constituent.

Brass and bronze are examples of substitutional alloys, where some copper elements substitute for zinc and tin.

Interstitial Alloys

When atoms aren’t the same size, they can’t substitute into the base crystals. The atoms become trapped between the spaces in between the atoms, which is called the interstice. This is what makes an interstitial alloy.

Steel is an example of an interstitial alloy, where the carbon atom is too small to replace an atom, so it sits in the interstices of the matrix.

Substitutional and Interstitial Combinations

Some alloys could contain both substitutional and interstitial if the solute added includes elements that can replace atoms and elements that can sit within the interstices of the matrix.

Stainless steel is an example of a combination of the two, as carbon atoms fit into the interstices and chromium and nickel replace some of the atoms.

4. What is the Purpose of an Alloy?

Alloys are mainly made for commercial purposes and serve industries such as oil and gas, motorsport and petrochemicals and refineries.

6 Reasons Alloys Are Useful:

1. Increase Hardness – pure metals are soft, which doesn’t bode well if you’re using it in hot environments or for structural purposes. Combining metals makes them stronger.

2. Lower Melting Point – pure metals have a high melting point, so when they combine with other metals they’re easier to fuse.

3. Increase Tensile Strength – pure metals have a high melting point, so when they combine with other metals they’re easier to fuse.

4. Enhance Corrosion Resistance – in their pure form, metals are reactive. Alloying a metal improves its inertness, which enhances corrosion resistance

5. Modify Colour – metals can be combined, so they take on a different colour form.

6. Better Castability –pure metals contract when cast whereas alloys expand, which makes them better for casting.

What Industries Use Alloys?

Alloys have various strengths, and many industries that require them for different reasons.

- Aerospace and petrochemicals – the equipment used in these industries is often open to a lot of heat exposure, so heat resistant alloys are a popular choice.

- Oil & gas – oil and gas extraction occurs in harsh environments, which includes out at sea. Stainless steel is an ideal material for these structures because of its resistance to water and strength.

- Transportation – vehicles are composed of alloy metal, and there are various types of metal you need to make cars, buses and trains, which include steel and aluminium. Steel makes the framework, and aluminium is a common metal used for wheels and engine blocks.

Do You Know What an Alloy is?

Let’s recap the main point of this article, which is to summarise what an alloy is:

‘A metal made by combining two or more metallic elements’.

In its purest form, that’s what an alloy is. If you want to find out more about alloys, take a look at our technical resources.

Interested in buying alloys for comercial use? NeoNickel supply specialist alloys for a huge range of applications. Browse our website of get in touch with us for more info.